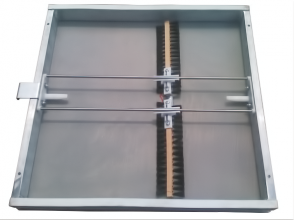

Used to clean and classify semolina for minimizing ash content in flour. The product uniformly spreads onto sieve by a screen. Bran or bran type materials and flour on surface of semolina are separated by air aspiration and purged semolina is classified by sieves according to its particle size. After cleaning, semolina is sent to Roller Mills for grinding.

| Model Modele |

Capacity Capacité |

Air Required m3/min Debit D’Air Necessaire m3/min | Vibratory Motor kw Moteur A Balourd | Amplitude (mm) | Rpm rev./min Tr/min | Sieve Area m2 Surface Tamisage |

Weight kg Poids kg |

Shipping Volume m3 Volume D’emballage | |||||||

| Wooden Bois |

Aluminium | Net | Gross Brut |

||||||||||||

| MP 500 | Depends on the product Dêpends Du Produit |

40-70 | 2x0.20 | 0-9 | 590 | 4.5 | 5 | 1300 | 1600 | 7.1 | |||||

| MP 600 | Depends on the product Dêpends Du Produit |

60-90 | 2x0.20 | 0-9 | 590 | - | 7.5 | 1500 | 1800 | 9.3 | |||||

| MP 1000 | Depends on the product Dêpends Du Produit |

80-140 | 2x0.20 | 0-9 | 590 | 9 | 10 | 2750 | 3100 | 13.2 | |||||

| 2x0.20 | |||||||||||||||

| MP 1200 | Depends on the product Dêpends Du Produit |

120-180 | 2x0.20 | 0-9 | 590 | - | 15 | 3300 | 3500 | 19 | |||||

| 2x0.20 | |||||||||||||||