Until recently, the animals have been fed by primitive methods in the world. In parallel with the technology improvents and welfare level rise of public, animal feed factories have been developed and the animals have begun to fed by modern methods.

Thanks to modern feed industry it is possible to increase meat, milk and egg productions of animals more than two times. Besides, by means of healty nutrition, animal diseases and lost can be prevented.

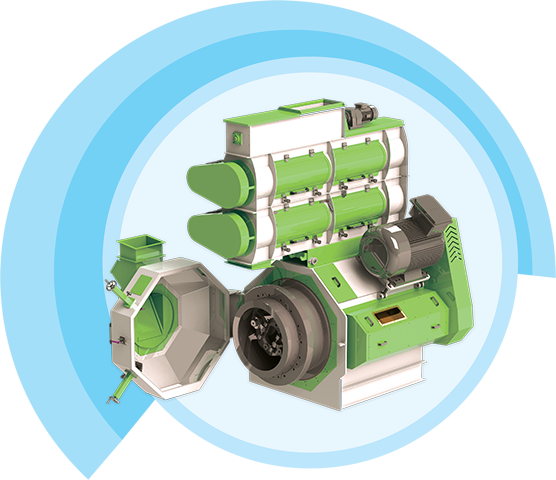

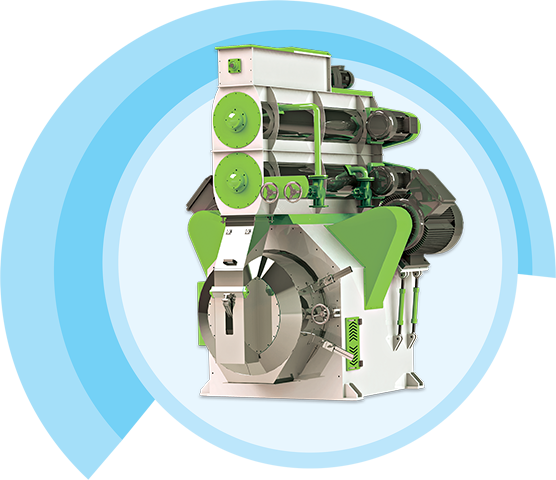

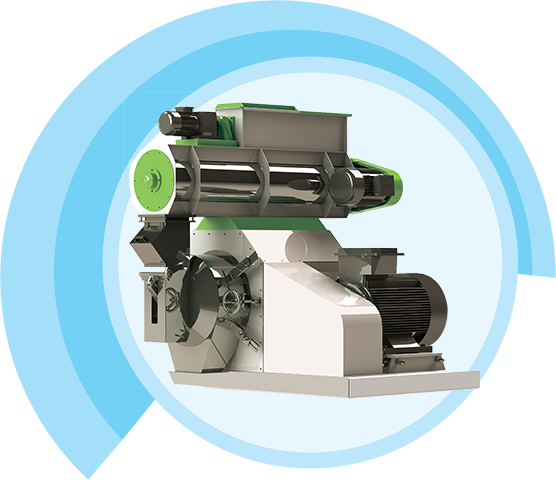

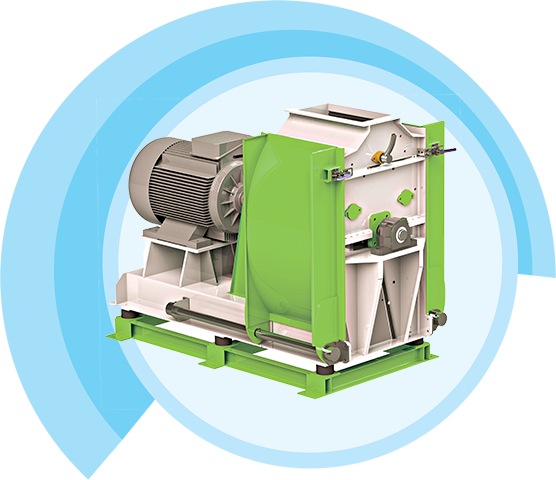

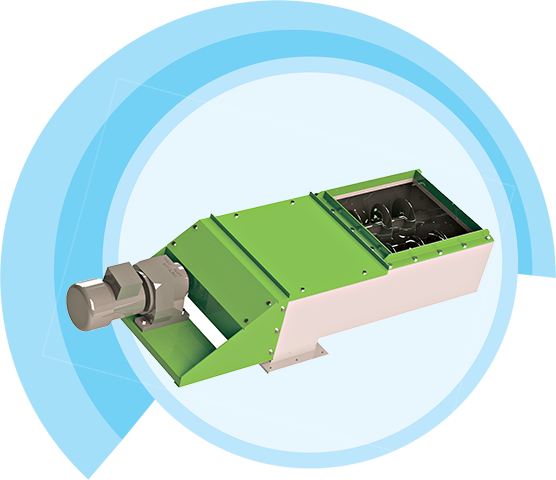

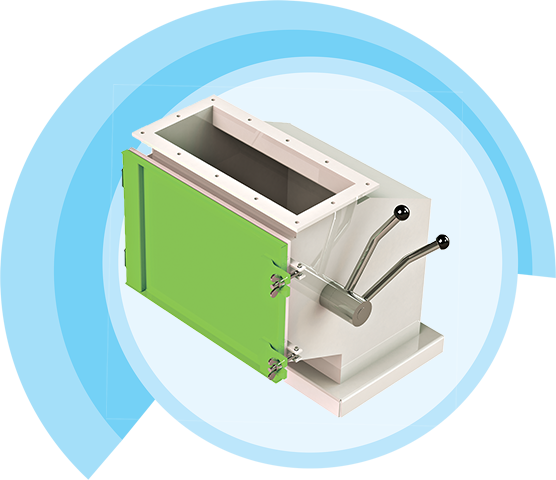

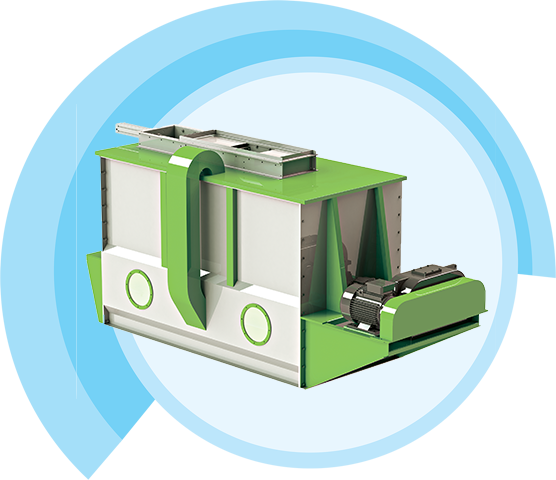

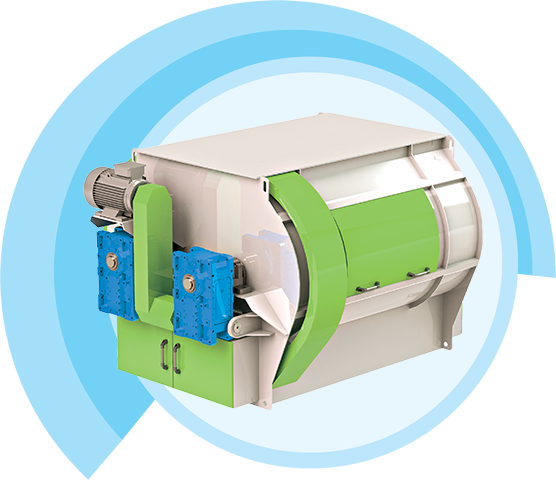

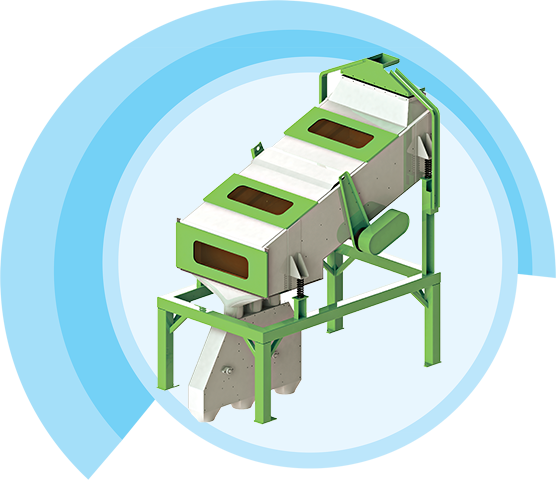

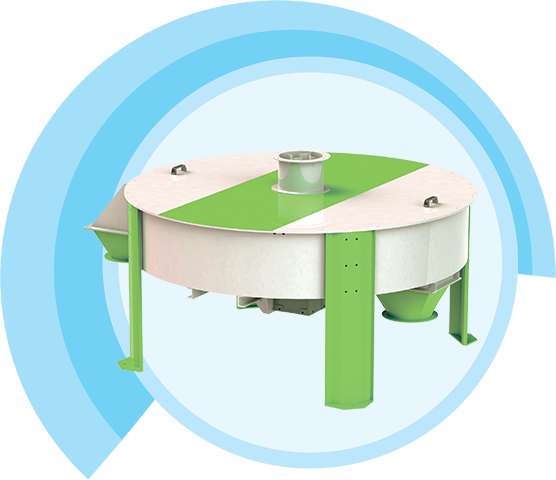

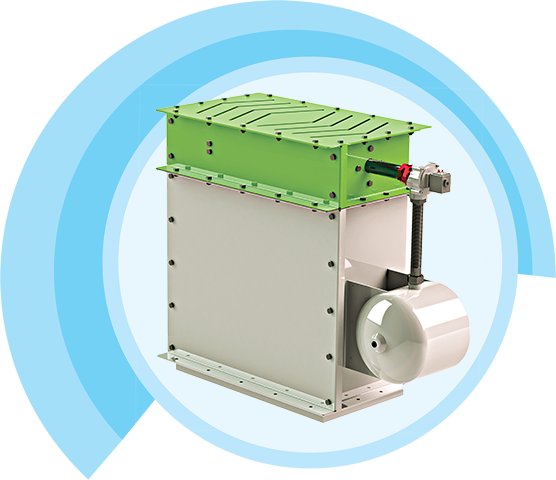

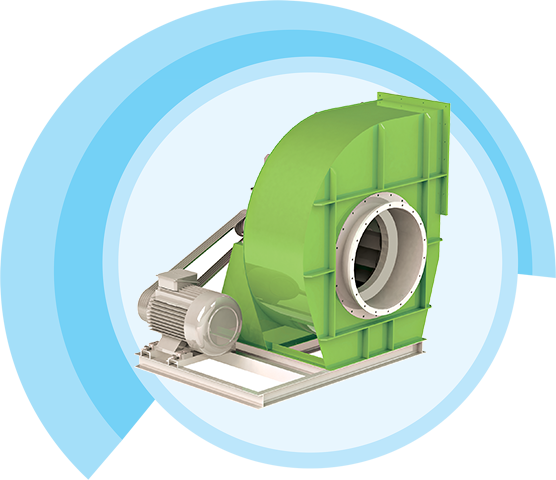

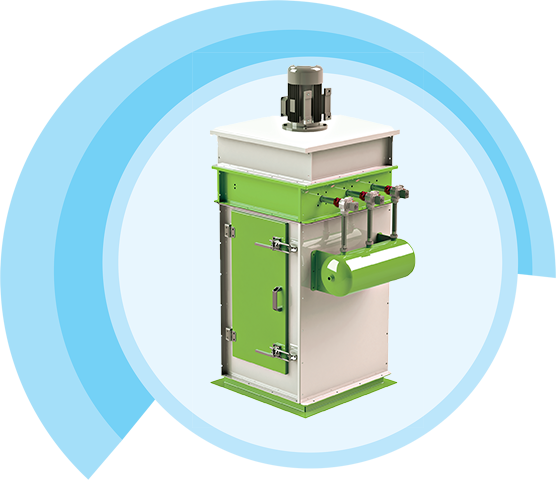

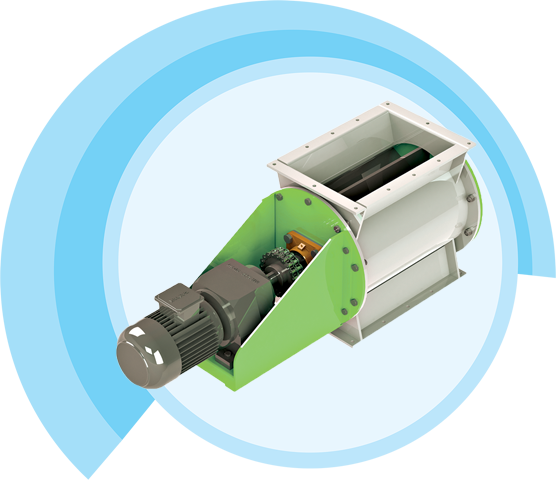

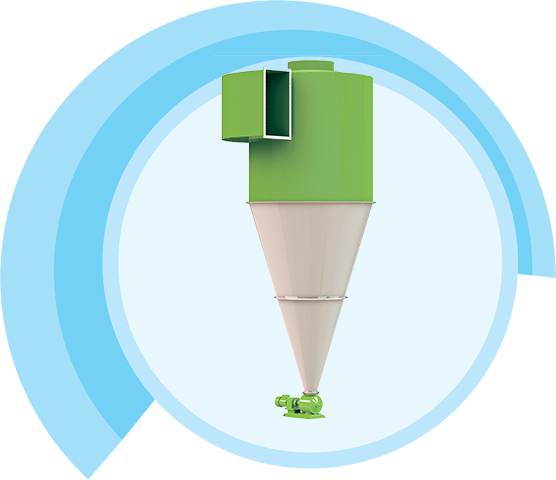

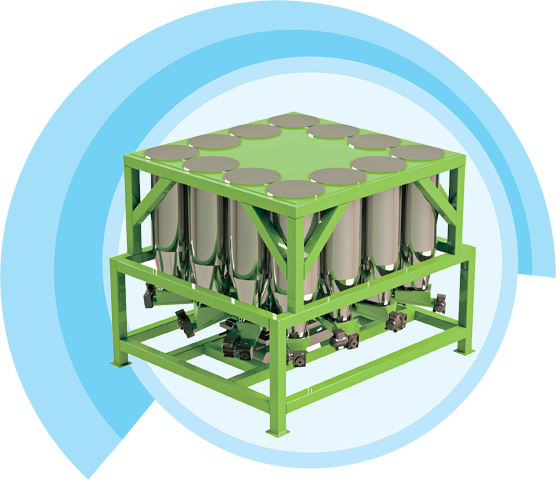

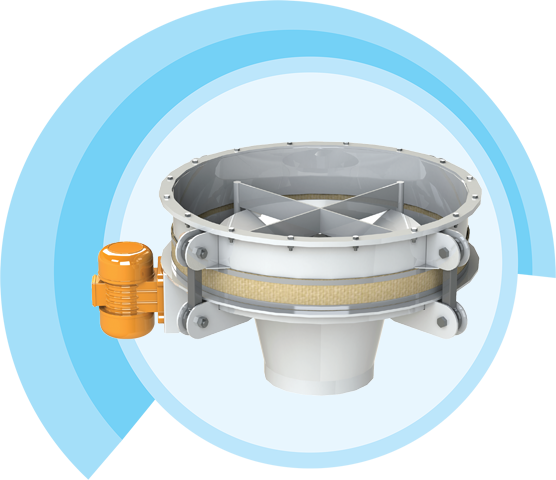

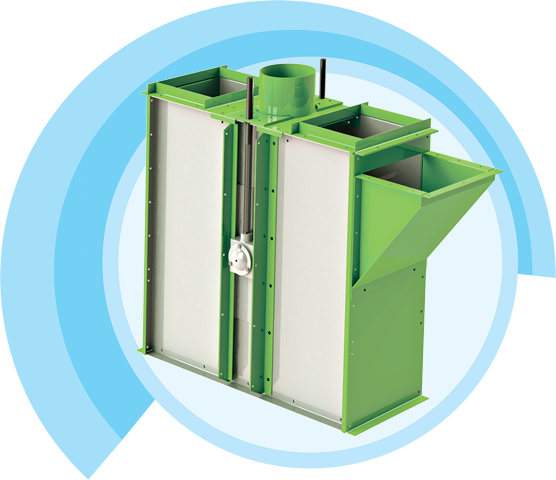

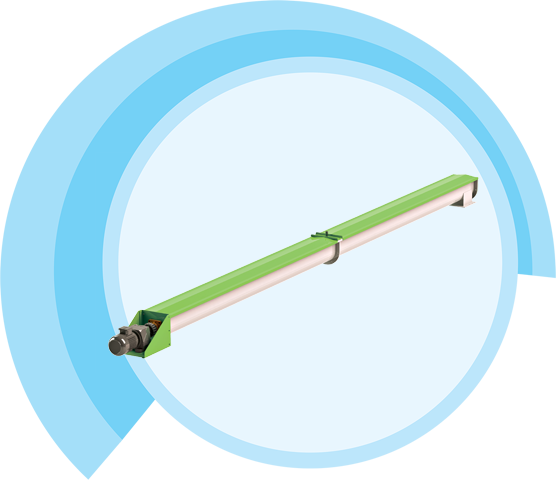

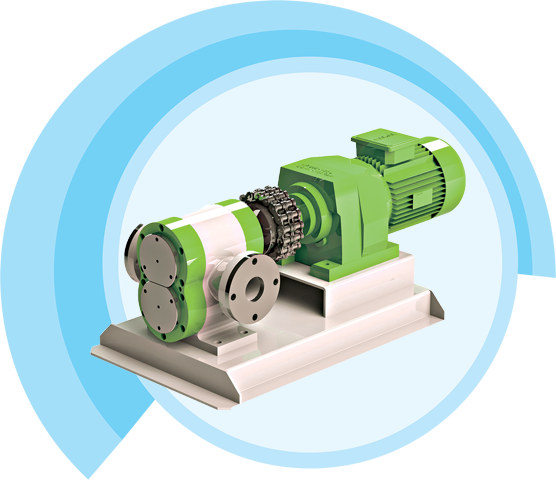

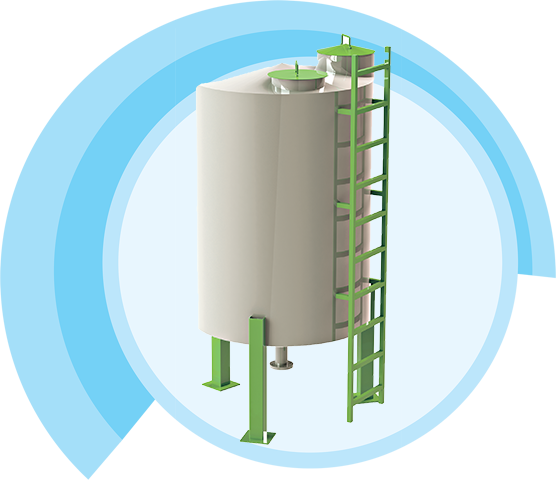

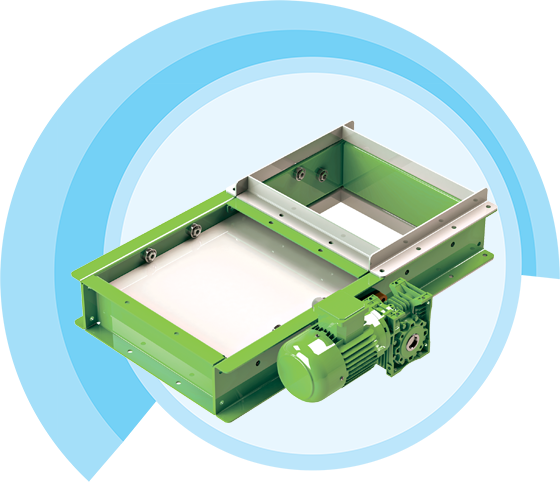

In general, the main units in a feed factory are, feed stuff formulation, grinding, mixing, pressing and packaging processes.

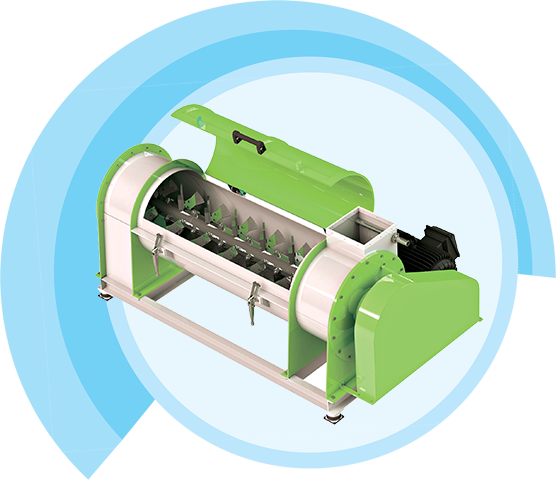

Homogenous mixing is essential so as to ensure that the animal eats properly.

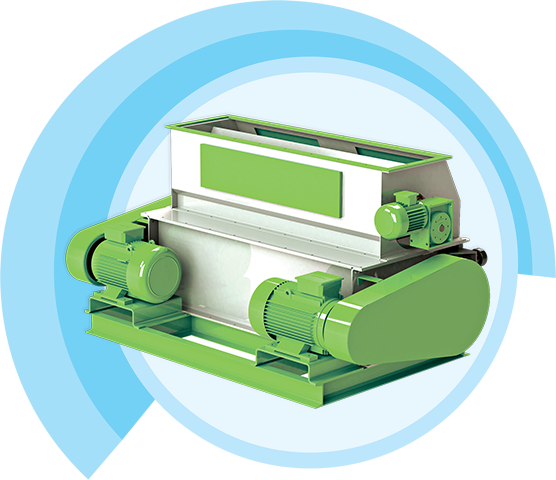

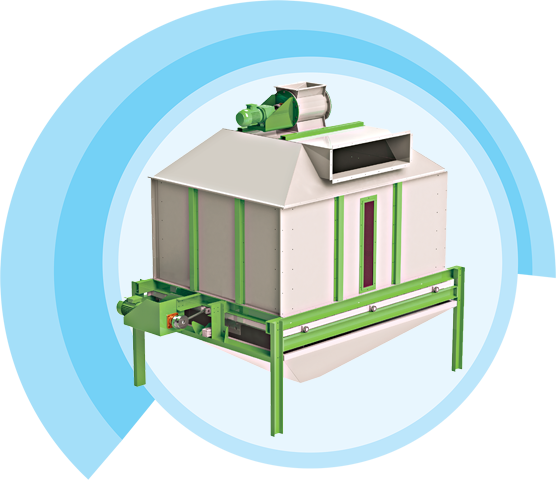

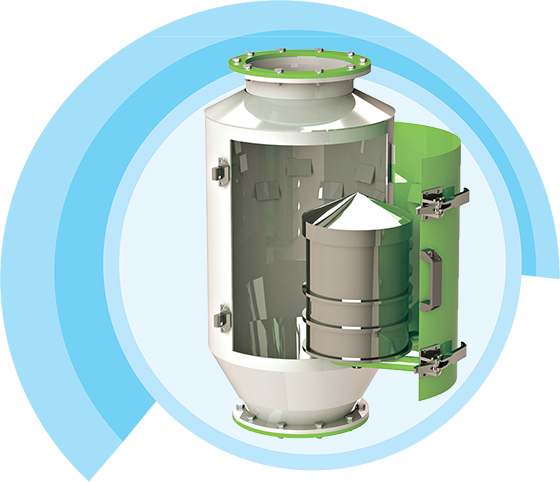

It is important pressing the mixed feed into pellets with hot vapor so as to expose the starch in cereals for easy and effective digestion, to disinfect the feed from microbial harmful contents and to ensure the animak to eat some useful particles that it doesn’t want to. Thanks to pelletizing process it is also possible to increase the yield from the animal two times with respect to other traditional grinding and mixing processes.

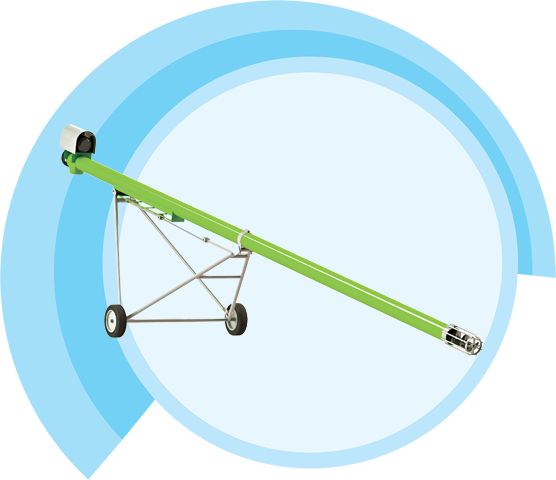

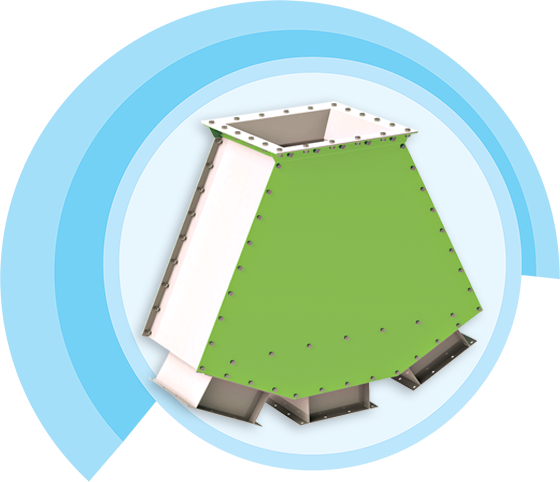

The capacity and flow rate calculation of the main machines and transport equipments, sufficient quality norms and conformity standards, integration of a robust automation system to provide sequential, synchronize and continuous operation are mandatory points to have an ideal and problem free feed factory.

The only way to obtain all these capabilities is to cooperate with expert, trained and experienced teams. Mozaik is always with you for this.